The most common method for plotting a stress and strain curve is to subject a rod of the test piece to a tensile test. Web in the linear limit of low stress values, the general relation between stress and strain is. Web introduction stress strain curve | mechanical properties of solids | aasoka aasoka 163k subscribers subscribe 6.7k 258k views 5 years ago science videos | learn with aasoka aasoka presents a. (1.4.1) σ e = p a 0, ϵ e = δ l 0. It has two claws that hold the two extremes of the rod and pull it at a uniform rate.

This is done using a universal testing machine. Web introduction stress strain curve | mechanical properties of solids | aasoka aasoka 163k subscribers subscribe 6.7k 258k views 5 years ago science videos | learn with aasoka aasoka presents a. The most common method for plotting a stress and strain curve is to subject a rod of the test piece to a tensile test. As we can see from dimensional analysis of this relation, the elastic modulus has the same physical unit. (1.4.1) σ e = p a 0, ϵ e = δ l 0.

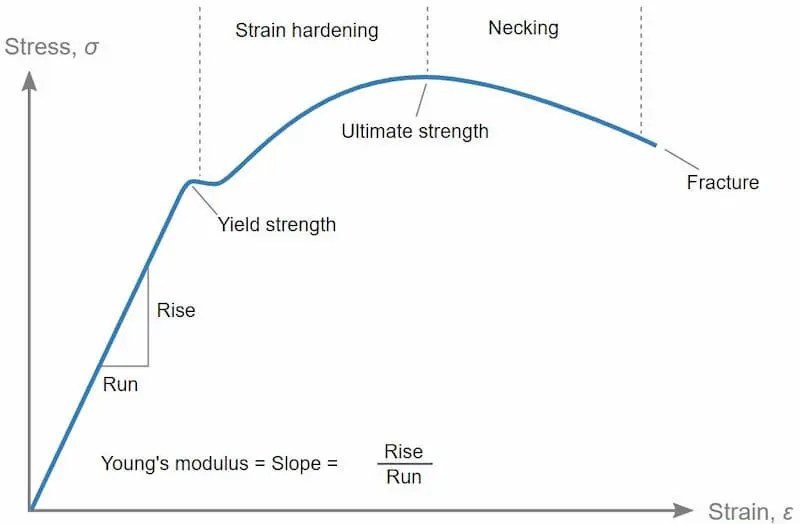

It has two claws that hold the two extremes of the rod and pull it at a uniform rate. Stress = (elastic modulus) × strain. They allow important information such as a material's elastic modulus and yield stress to be determined. It is obtained by gradually applying load to a test coupon and measuring the deformation, from which the stress and strain can be determined (see tensile testing ). The most common method for plotting a stress and strain curve is to subject a rod of the test piece to a tensile test.

Accurate knowledge of these parameters is paramount in engineering design. Web a significant barrier to my understanding of typical engineering stress vs. (1.4.1) σ e = p a 0, ϵ e = δ l 0. Web introduction stress strain curve | mechanical properties of solids | aasoka aasoka 163k subscribers subscribe 6.7k 258k views 5 years ago science videos | learn with aasoka aasoka presents a. This is done using a universal testing machine. Web in the linear limit of low stress values, the general relation between stress and strain is. The most common method for plotting a stress and strain curve is to subject a rod of the test piece to a tensile test. It has two claws that hold the two extremes of the rod and pull it at a uniform rate. They allow important information such as a material's elastic modulus and yield stress to be determined. As we can see from dimensional analysis of this relation, the elastic modulus has the same physical unit. Stress = (elastic modulus) × strain. It is obtained by gradually applying load to a test coupon and measuring the deformation, from which the stress and strain can be determined (see tensile testing ).

The Most Common Method For Plotting A Stress And Strain Curve Is To Subject A Rod Of The Test Piece To A Tensile Test.

Accurate knowledge of these parameters is paramount in engineering design. This is done using a universal testing machine. Web introduction stress strain curve | mechanical properties of solids | aasoka aasoka 163k subscribers subscribe 6.7k 258k views 5 years ago science videos | learn with aasoka aasoka presents a. Web a significant barrier to my understanding of typical engineering stress vs.

It Has Two Claws That Hold The Two Extremes Of The Rod And Pull It At A Uniform Rate.

They allow important information such as a material's elastic modulus and yield stress to be determined. (1.4.1) σ e = p a 0, ϵ e = δ l 0. As we can see from dimensional analysis of this relation, the elastic modulus has the same physical unit. Web in the linear limit of low stress values, the general relation between stress and strain is.

It Is Obtained By Gradually Applying Load To A Test Coupon And Measuring The Deformation, From Which The Stress And Strain Can Be Determined (See Tensile Testing ).

Stress = (elastic modulus) × strain.