1/4” stud welds on the arrow side with a. Web how to read weld symbols print article learn how to read common welding symbols and their meaning. Web this article will provide 9 easy steps for how to read welding symbols so that you can understand them quickly and accurately. 3/16” spot weld on the arrow side, ground flush, a pitch of 2”, and 8 total welds. 1” stud welds on the arrow side, 2” pitch, 20 total studs.

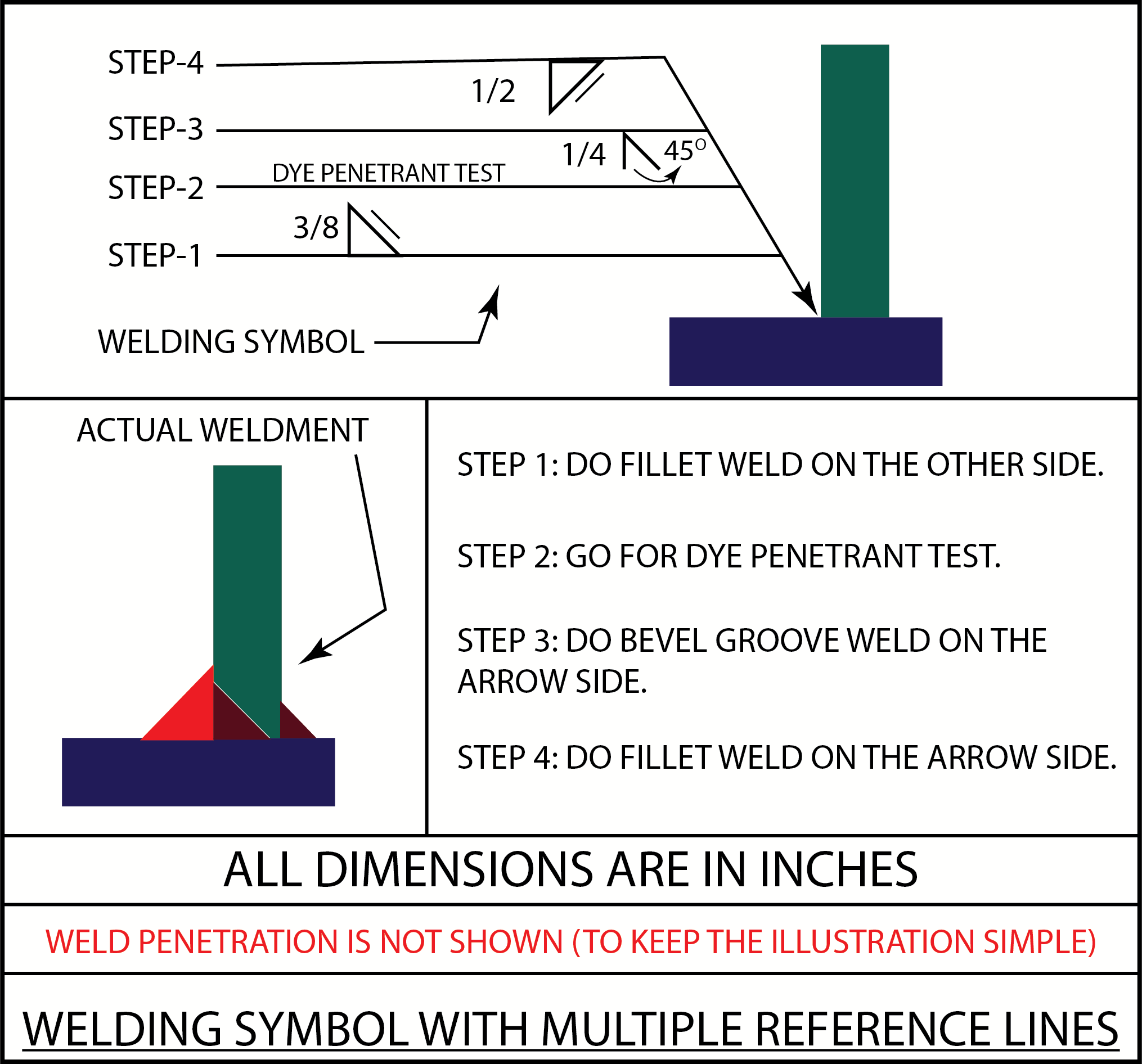

You will often find these on engineering and fabrication drawings. Web there are three main elements to a weld symbol: Web this video explains what weld symbols are, and how to identify their meaning when drawn on a reference line. How to read a welding symbol. The reference line is a horizontal line that is used to align the other elements of the symbol.

You will often find these on engineering and fabrication drawings. The one end of a leader line is connected to a horizontal line known as the reference line. This line is the base line for the weld symbol and all other elements of the symbol will be referenced from this line. The arrow connects the reference line to the joint which is being welded. By christopher mcdonagh reviewed by thomas garcia last updated:

This line is the base line for the weld symbol and all other elements of the symbol will be referenced from this line. Web this article will provide 9 easy steps for how to read welding symbols so that you can understand them quickly and accurately. The base platform this symbol is a simple platform for displaying the characteristics and surrounding details for your welds. The reference line is a horizontal line that is used to align the other elements of the symbol. The arrow may point up or down the arrow does not necessarily need to point to the side of the joint that needs to be welded. Web this video explains what weld symbols are, and how to identify their meaning when drawn on a reference line. Web a complete guide to weld symbols: The arrow is used to point to the location of the weld, and the tail contains information about the type of weld, size, and other details. This is where the details are placed about the type of weld and the specific location. The arrow connects the reference line to the joint which is being welded. Web on every welding symbol, you’ll see an arrowhead that directs you to the location of the weld. The arrow points toward the joint being welded, and this joint will always have two sides. Points to the general location of the weld. 1” stud welds on the arrow side, 2” pitch, 20 total studs. Common weld symbols and their meanings a set of symbols are shorthand for describing the type of weld, its size, and other processing and finishing information.

This Line Is The Base Line For The Weld Symbol And All Other Elements Of The Symbol Will Be Referenced From This Line.

Web on every welding symbol, you’ll see an arrowhead that directs you to the location of the weld. Web this article will provide 9 easy steps for how to read welding symbols so that you can understand them quickly and accurately. Their structure, what different lines mean, and what standards there are. Common weld symbols and their meanings a set of symbols are shorthand for describing the type of weld, its size, and other processing and finishing information.

Resistance Seam Weld With No Side Significance, 8” Pitch, 16” Length.

In the space below draw a symbol for the following: Reference line, arrow line, and the tail. The reference line is a horizontal line that is used to align the other elements of the symbol. Web a complete guide to weld symbols:

How To Read Them We Explain The Basics Of Weld Symbols:

Web every weld symbol must consist of an arrow and a reference line. This is where the details are placed about the type of weld and the specific location. Web this video explains what weld symbols are, and how to identify their meaning when drawn on a reference line. Web spot, stud, seam quiz.

Web There Are Three Main Elements To A Weld Symbol:

The arrow is used to point to the location of the weld, and the tail contains information about the type of weld, size, and other details. The one end of a leader line is connected to a horizontal line known as the reference line. How to read a welding symbol. You will often find these on engineering and fabrication drawings.